Newcrest: Crusher Wear Life at Telfer Mine Site

At Newcrest’s Telfer mine there are several gyratory crushers used to crush hard rock ore. Newcrest required a reliable tool to inform the planning, maintenance and reliability teams of crusher shutdown dates. These dates need to be planned based on wear rates of the crusher mantle and crusher concave liner.

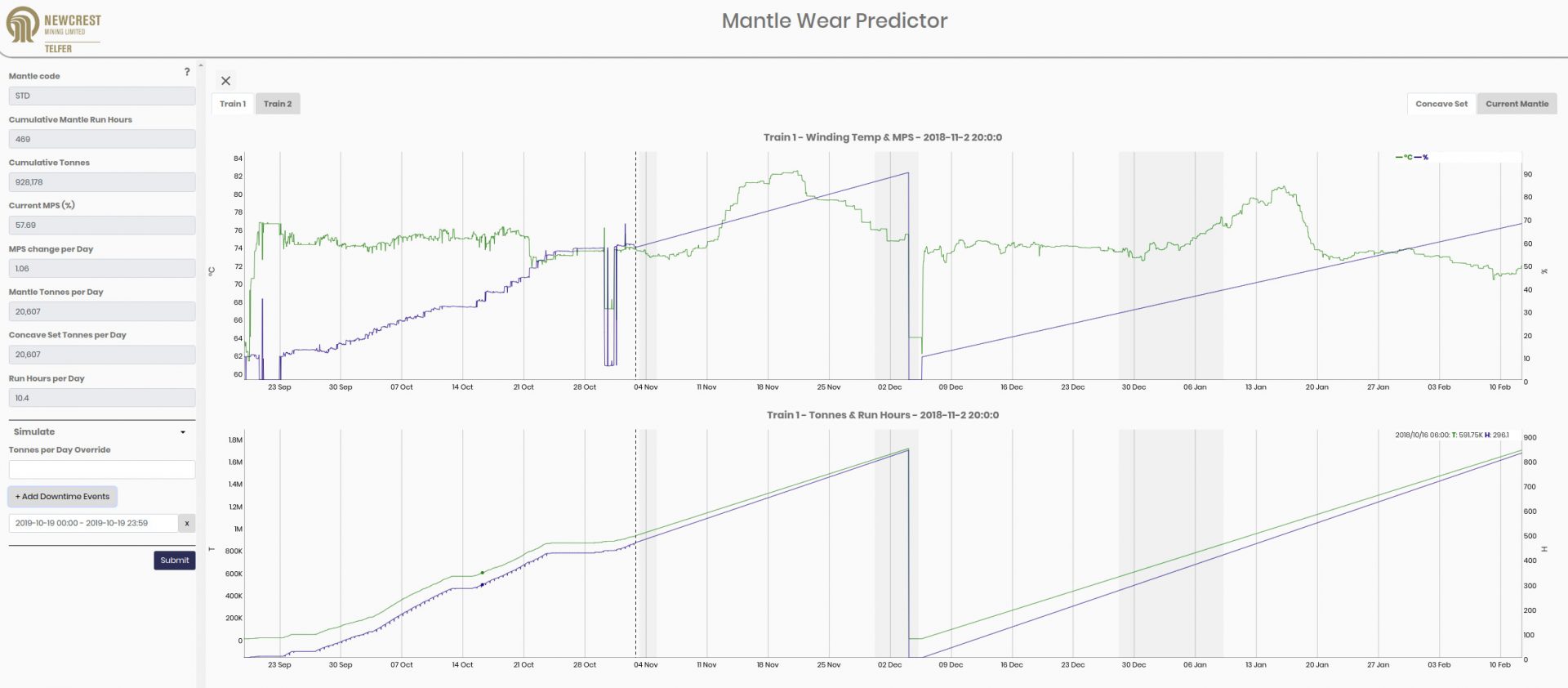

With no sensors available to directly measure wear rates, we were tasked with predicting wear rates and ideal shutdown dates for each of the crushers. We analysed four years of Pi Historian Data collected from sensors that report mantle position, run hours, winding temperature and power consumption.

Our analysis yielded findings that enabled us to devise an ensemble of models that predict Winding Temperature, Run Hours, Mantle Position and Cumulative Tonnes several months ahead. We used linear models for the variables Run Hours, Tonnes and Mantle Position since they exhibit linear trending

We presented our model inference via a

The application also allows the user to simulate more aggressive or more passive mining scenarios to see the effect on predicted crusher wear life.

Similar approaches can be leveraged for a range of process optimisation problems in many industries, please get in contact if you have a similar situation.